NEOMACHINE MFG.CO.P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to NEOMACHINE MFG.CO.P.LTD.

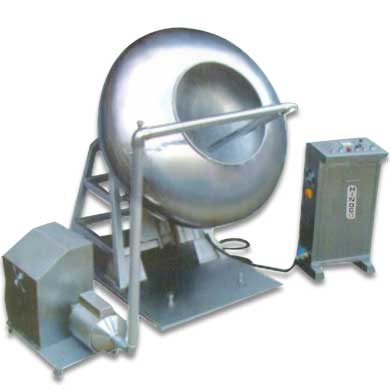

Automatic Coating System

NEOCOTA have been designed to comply with current US FDA and other international legislations as well as anticipated trends.

Apart from Main Pan Cabinet, NEOCOTA has the Air Handling System, the Spray System, the Control and Documentation System among others, to enable the user to maintain standards for the entire range of coating operations.

Flexible Design

NEOCOTA is a truly flexible system for aqueous or organic solvent based film coating.

NEOCOTA is also suitable for sugar coating.

NEOCOTA is equally suitable for loading of drugs on tablets and pellets during film coating or sugar coating. Due to its unique design features, it is possible to coat tablets and pellets of any size and shape in NEOCOTA.

Truly Automatic

NEOCOTA can run any coating programme without manual intervention.

NEOCOTA performs any coating programme without constant operator's assistance.

The menu-driven system can be run either through the work station placed in the coating area or through supervisory station with suitable interface equipped with to-and-fro communication ability.

Data collection can be alphanumerical and/or graphical to monitor ongoing operation and to detect fault, in case of mechanical failure.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.